- Capacity: 300MT x 2

- Length: 6000mm x 2

- Synchronize: Electric-Mechanic

- Suitable Pole: Light pole

- Conic pole plate thickness: 3~4mm

- Octagonal pole thickness: 3~6mm

- E21 NC controller

it is suitable for one piece type polygonal and circle taper light pole. it is automatic welding line, the trolley with inverter speed adjustable motor can pull the light pole from small end to big end, The hydraulic cylinder through mechanical chain, worm wheel push the clamping wheel to close the pole and do welding at same time.

Normal materials can be used for steel poles. Mild steel is most common. while if with structure steel, pole size can be smaller or stronger with same size.

Similar Material : SS400 (JIS), S235 (DIN), E235B (ISO 630)

Yield strength(σs) : ~ 235Mpa

Tensile strength (σb): Nominal 450Mpa (370~500Mpa)

Elongation (δ5/%):≥26%

Elastic Modulus (E) : 200~210 Gpa

Similar Material : Gr.42 (AST), SPFC490 (JIS), E295 (DIN), S275JR

Yield strength(σs) : ~ 295Mpa

Tensile strength (σb): 390~570Mpa

Elongation (δ5/%):≥23%

Similar Material : Gr.50 (AST), SPFC590 (JIS), S355 (DIN), E355 (ISO 630)

Yield strength(σs) : ~ 345Mpa

Tensile strength (σb): 450~630Mpa

Elongation (δ5/%):≥17%

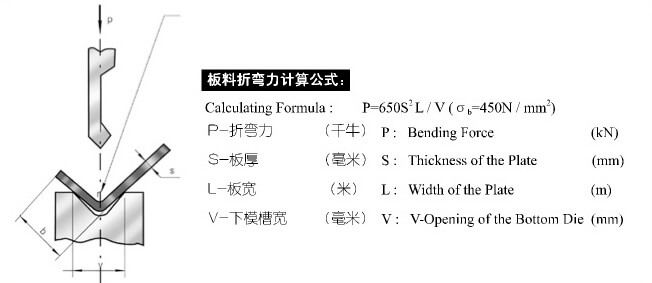

For polygonal steel poles (octagonal), bending force calculation is steel plate air bending. we can estimate in following form. while for conic pole, it is complete press bending. force will be higher. There is no exact calculation formula.