In china, there are different types poles used for public street lighting, Like cement pole, steel light pole, Aluminium light pole or FRP light pole.

1.Wood light poles

In history, limited by pole making technology, most countries lighting pole were made from wood. now it was history in most countries. of course, we still can see such poles in some Forest-based countries.

In history, limited by pole making technology, most countries lighting pole were made from wood. now it was history in most countries. of course, we still can see such poles in some Forest-based countries.

2. Cement Light Pole

Cement poles were used a long time in china. It was our childhood memory. Because of its heavy weight, large transportation cost, and relatively dangerous, the market has gradually phased out this kind of street light pole.

Cement poles were used a long time in china. It was our childhood memory. Because of its heavy weight, large transportation cost, and relatively dangerous, the market has gradually phased out this kind of street light pole.

3. Steel Light Poles

Iron street light pole, also known as high-quality Q235 steel light pole. It is made of high-quality Q235 steel, hot-dip galvanized and spray-coated. It can be rust-free for 30 years and is very hard. This is the most common and used street lamp pole in the street lamp market.

Iron street light pole, also known as high-quality Q235 steel light pole. It is made of high-quality Q235 steel, hot-dip galvanized and spray-coated. It can be rust-free for 30 years and is very hard. This is the most common and used street lamp pole in the street lamp market.

4. FRP (Fiber Reinforced Polymer) Lighting Pole

Glass fiber reinforced plastic light pole is an inorganic non-metallic material with excellent performance. There are many types. The advantages are good insulation, strong heat resistance, good corrosion resistance and high mechanical strength. Therefore, not many are used in the market.

Glass fiber reinforced plastic light pole is an inorganic non-metallic material with excellent performance. There are many types. The advantages are good insulation, strong heat resistance, good corrosion resistance and high mechanical strength. Therefore, not many are used in the market.

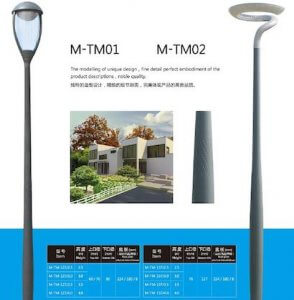

5. Aluminium Alloy Lighting pole

Aluminum alloy street light poles are made of high-strength aluminum alloy. The manufacturer not only protects human safety, but also has high strength, does not require any surface treatment, has more than 50 years of corrosion resistance, and is very beautiful. Looks more upscale. Aluminum alloy has better physical and mechanical properties than pure aluminum: easy processing, high durability, wide application range, good decorative effect, rich colors and so on. Most of this street light poles are exported overseas, especially in developed countries.

Aluminum alloy street light poles are made of high-strength aluminum alloy. The manufacturer not only protects human safety, but also has high strength, does not require any surface treatment, has more than 50 years of corrosion resistance, and is very beautiful. Looks more upscale. Aluminum alloy has better physical and mechanical properties than pure aluminum: easy processing, high durability, wide application range, good decorative effect, rich colors and so on. Most of this street light poles are exported overseas, especially in developed countries.

6. Stainless Steel Light Poles

Stainless steel light poles have the best chemical and electrochemical resistance in steel, second only to titanium alloys. The method adopted by our country is to perform hot-dip galvanizing surface treatment. The product life of hot-dip galvanizing products that meet international standards can reach 15 years. Otherwise it is far from reaching. Mostly used in courtyards, communities, parks and other places. Heat resistance, high temperature resistance, low temperature resistance and even ultra low temperature resistance.

Stainless steel light poles have the best chemical and electrochemical resistance in steel, second only to titanium alloys. The method adopted by our country is to perform hot-dip galvanizing surface treatment. The product life of hot-dip galvanizing products that meet international standards can reach 15 years. Otherwise it is far from reaching. Mostly used in courtyards, communities, parks and other places. Heat resistance, high temperature resistance, low temperature resistance and even ultra low temperature resistance.